| Cables for Oil Industry | |||

![]() Screened TFN Cable

Screened TFN Cable

Applications

These cables are use in class 1, Division 2 Hazardous locations, may be installed in trays, wire ways,

ducts, conduit and aerially when properly supported by a messenger. They are approved for direct

burial, wet or dry locations and outdoors in cable trays where a sunlight resistant rating is required.

Standards

ICEA S-73-532; UL 1277; UL 66

Construction

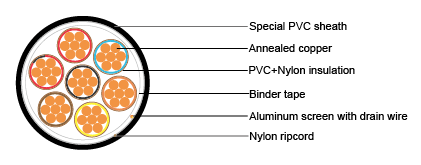

Conductor: Bare, annealed copper conforming to ASTM B3 and B8

Insulation: Flame-retardant PVC/Nylon type TFN per UL 66

Color coded per Method #1-E2 per ICEA S-73-532

Binder tape

Screen: Aluminum tape

Drain Wire: 18 AWG (7w) tinned copper for 16 AWG conductor

20 AWG (7w) tinned copper for 18 AWG conductor

Ripcord: Nylon

Jacket: Special PVC, flame retardant, UL listed sunlight and moisture resistant, meeting the

requirements of UL 1277. Color: Black

Chemical resistance: Aliphatic and aromatic hydrocarbon resistance

16 AWG, 600V, Rated 90°C

No. of Cores |

PVC Thickness |

Nylon Thickness |

Jacket Thickness |

Nom. O.D. |

Approx. Weight |

Ampacity |

mm |

mm |

mm |

mm |

kg/km |

amps |

|

2 |

0.38 |

0.10 |

1.14 |

7.57 |

76 |

8.0 |

3 |

0.38 |

0.10 |

1.14 |

7.98 |

100 |

8.0 |

4 |

0.38 |

0.10 |

1.14 |

8.61 |

119 |

6.4 |

5 |

0.38 |

0.10 |

1.14 |

9.35 |

143 |

6.4 |

6 |

0.38 |

0.10 |

1.14 |

10.11 |

165 |

6.4 |

7 |

0.38 |

0.10 |

1.14 |

10.11 |

179 |

5.6 |

8 |

0.38 |

0.10 |

1.14 |

11.05 |

202 |

5.6 |

9 |

0.38 |

0.10 |

1.14 |

11.86 |

222 |

5.6 |

10 |

0.38 |

0.10 |

1.14 |

12.62 |

240 |

4.0 |

11 |

0.38 |

0.10 |

1.14 |

12.80 |

257 |

4.0 |

12 |

0.38 |

0.10 |

1.52 |

13.94 |

278 |

4.0 |

13 |

0.38 |

0.10 |

1.52 |

14.17 |

317 |

4.0 |

14 |

0.38 |

0.10 |

1.52 |

14.61 |

341 |

4.0 |

15 |

0.38 |

0.10 |

1.52 |

14.96 |

360 |

4.0 |

19 |

0.38 |

0.10 |

1.52 |

16.10 |

448 |

4.0 |

20 |

0.38 |

0.10 |

1.52 |

16.56 |

461 |

4.0 |

25 |

0.38 |

0.10 |

1.52 |

18.47 |

561 |

3.6 |

30 |

0.38 |

0.10 |

1.52 |

19.69 |

655 |

3.6 |

37 |

0.38 |

0.10 |

2.03 |

22.20 |

845 |

3.2 |

40 |

0.38 |

0.10 |

2.03 |

22.99 |

899 |

3.2 |

45 |

0.38 |

0.10 |

2.03 |

24.26 |

995 |

2.8 |

50 |

0.38 |

0.10 |

2.03 |

25.12 |

1106 |

2.8 |

18 AWG, 600V, Rated 90°C

No. of Cores |

PVC Thickness |

Nylon Thickness |

Jacket Thickness |

Nom. O.D. |

Approx. Weight |

Ampacity |

mm |

mm |

mm |

mm |

kg/km |

amps |

|

2 |

0.38 |

0.10 |

1.14 |

7.11 |

57 |

6.0 |

3 |

0.38 |

0.10 |

1.14 |

7.47 |

73 |

6.0 |

4 |

0.38 |

0.10 |

1.14 |

8.06 |

86 |

4.8 |

5 |

0.38 |

0.10 |

1.14 |

8.71 |

108 |

4.8 |

6 |

0.38 |

0.10 |

1.14 |

9.40 |

122 |

4.8 |

7 |

0.38 |

0.10 |

1.14 |

9.40 |

136 |

4.2 |

8 |

0.38 |

0.10 |

1.14 |

10.26 |

145 |

4.2 |

9 |

0.38 |

0.10 |

1.14 |

10.99 |

167 |

4.2 |

10 |

0.38 |

0.10 |

1.14 |

11.68 |

188 |

3.0 |

11 |

0.38 |

0.10 |

1.14 |

11.84 |

193 |

3.0 |

12 |

0.38 |

0.10 |

1.14 |

12.18 |

202 |

3.0 |

13 |

0.38 |

0.10 |

1.14 |

12.39 |

214 |

3.0 |

14 |

0.38 |

0.10 |

1.14 |

12.77 |

228 |

3.0 |

15 |

0.38 |

0.10 |

1.14 |

13.09 |

245 |

3.0 |

19 |

0.38 |

0.10 |

1.52 |

14.88 |

320 |

3.0 |

20 |

0.38 |

0.10 |

1.52 |

15.30 |

326 |

3.0 |

25 |

0.38 |

0.10 |

1.52 |

17.01 |

416 |

2.7 |

30 |

0.38 |

0.10 |

1.52 |

18.11 |

473 |

2.7 |

37 |

0.38 |

0.10 |

1.52 |

19.46 |

580 |

2.4 |

40 |

0.38 |

0.10 |

1.52 |

20.17 |

606 |

2.4 |

45 |

0.38 |

0.10 |

2.03 |

22.32 |

673 |

2.1 |

50 |

0.38 |

0.10 |

2.03 |

23.10 |

783 |

2.1 |